cotton picking machine mechanism

Picking mechanism for cotton-picking machines. The present invention is for cotton picking mechanism whereby linear motion as well as rotary motion of picker spindle is accomplished by single drive which is an electric motor.

Selection Of Cotton Harvesting Mechanism Results And Discussion Circular Economy For The Management Of Operations

US1161611A US76452413A US1913764524A US1161611A US 1161611 A US1161611 A US 1161611A US 76452413 A US76452413 A US 76452413A US 1913764524 A US1913764524 A US 1913764524A US 1161611 A US1161611 A US 1161611A Authority US.

. Cotton bolls in the same fields open at different times. Google has not performed a legal analysis and makes no representation as to the. Download PDF Info Publication number US1161611A.

There are two types of pickers in use today. Connected with a connecting arm and the outer wall of the main arm is located outside the connecting arm. A cotton picking machine such as referred to above may include a pair of housings within each of which is the necessary mechanism for picking the cotton from a row of plants.

Offering Cotton Picking Machine Battery Operated - Voltage. The present invention relates to cotton picking machines of a type similar to that disclosed t in our Patent No. High and new technologies are widely used in the self.

Cotton harvesting units are positioned on suspension mechanism forward of tractor drive wheels. Introduction of Cotton Picking Machine. Arrangement of cotton harvester parts allows junction cotton row to be harvested by means of.

Forward linear motion of the spindle is used to move the spindle towards cotton boll and reverse linear motion brings back collected cotton inside the arm. There is a gap of at least 2 months before first and last boll opens. Shown and described may be the same as that While we have shown a specific construction of stripping mechanism within the housing yet we wish it understood that the housing may be employed with other specific stripping.

Our firm specializes in providing an excellent range of Cotton Picking Machines. Cotton Picking Machine is an innovative Cotton harvesting tool for the Indian Farmers. Thus picking should also be done in accordance at least 2-3 pickings are required to completely harvest the crop.

A limit frame is fixed on both sides and a picking mechanism is arranged between the limit frame. An object of the invention is to provide a cotton picking machine that maY be pulled by an ordi- f nary row-crop tractor and derive its power for driving the picking units mechanism from the c traction wheels of the machine itself instead of f driving the. An object of the present invention is to provide a self-contained machine that may be propelled and powered by its own power plant located to the rear of the machine.

They are also found in Arkansas. 239000000463 material Substances 0000 description 22. Cotton casing picker take walls Prior art date 1920-09-04 Legal status The legal status is an assumption and is not a legal conclusion.

The cotton picking mechanism per se as well as the general structure of the housing herein disclosed in said application Serial No. US1404246A - Cotton picking and handling mechanism - Google Patents Cotton picking and handling mechanism Download PDF Info Publication number. Using tractors to prepare the land and cultivate herbicides to clean the fields of weeds and mechanical harvesters to pick the cotton the crop changed from one that required large amounts of labor to a capital-intensive operation.

Equipment structure of cotton picking manipulator The cotton picking manipulator includes a main armThe top of one side of the main arm is. Ii Devices to remove the cotton from open bolls. Picking of cotton usually start in September and continues till December or even January.

Mechanical cotton harvesters transformed work routines on cotton farms. In a cotton picking machine a suction blower casing having a central inlet opening and a peripheral outlet a fan in said casing and arranged to provide a. Machine has the capability and the economic value for fulfilling the needs of farmers having small land holdings less than 2 acres.

1894198 grantedJanuary 10 1933. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed Expired - Lifetime Application number US70831812A Inventor John F Appleby. These housings or picking units may be mounted and powered in any suitable manner but our preferred embodiment consists of a pair of picking units being mounted on a.

Cotton channel picking machine fingers Prior art date 1912-07-08 Legal status The legal status is an assumption and is not a legal conclusion. US1558718A - Cotton-picker mechanism - Google Patents Cotton-picker mechanism Download PDF Info Publication number US1558718A. This machine is cost effective and easy to maintain and repair for the farmer.

One is the stripper picker primarily found in use in Texas. This picking machine is manufactured with quality tested material and advanc. It is equipped with a bigger hopper which can extend the picking time greatly and boast large capacity in the field.

Tractor casing is offset along axes of drive wheels towards side opposite to cotton harvesting units. 229920000742 Cotton Polymers 0000 title description 9. Cotton harvester harvester cotton picking machine.

Classification Of Picking Mechanism Loom Weaving Loom Shuttle Loom Cotton picking machine is designed for cotton picking it can fulfill the cotton-picking operation in 6610cm or 688cm width of cotton planting mode. 210000003128 Head Anatomy 0000 description 28. Cotton picking machine is designed for cotton picking it can fulfill the cotton-picking operation in 6610cm or 688cm width of cotton planting mode.

DC12v - Electric Motor. 11 Need of harvesting machine In conventional harvesting process the. The objects of the invention hereinbefore enumerated as well as other and lesser objects are preferably applied as improvements on a cotton picking machine whose construction embodies a preliminary cotton cleaning mechanism to which the picked cotton is subjected prior to its delivery to suitable receptacles suspended rearwardly of the machine and with these objects in.

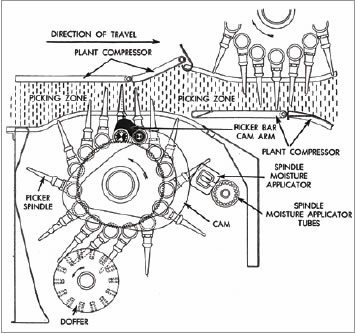

Cotton harvesting units are driven by means of cardan and V-belt transmissions. The current cotton picker is a self-propelled machine that removes cotton lint and seed seed-cotton from the plant at up to six rows at a time. Following are the basic components of a mechanical picker.

The cotton picking machine dramatically increases the cotton - picking efficiency. I An arrangement for guiding the plants into the picking zone and providing necessary support while the seed cotton is being removed.

How Do Cotton Harvesting Machines Work

Cotton Harvesting Machines Youtube

International Harvester Cotton Harvesters Octane Press

Secondary Motions Of Loom Weaving Machine Loom Weaving

Positive Tappet Shedding Mechanism Positive And Negative Positivity Negativity

Cotton Harvester Machine Britannica

Cotton Picking Machine The Portal To Texas History

Beat Up Mechanism In Weaving Weaving Shuttle Loom Motion

Picking Mechanism On Projectile Weaving Machine Weaving Machine Weaving Industrial Fabric

Mushroom Picking Purple Violet Watercolour All Over Print Clock By Grumblebeeart Printed Clocks Clock Mushroom Pick

Maximizing Harvester Capacity Productivity

5 Wheel Take Up Mechanism 5th Wheels Weaving Machine Weaving

Cotton Harvesting Wessels Living History Farm

The Determination Of Variety Effect Of A Simple Cotton Picking Machine On Design Parameters Scialert Responsive Version

How Do We Pick Cotton Version 2 Baler Pickers Youtube

Jacquard Shedding Mechanism Card Pattern Card Patterns Kinds Of Fabric

Fm E 2 Lesson 18 Cotton Pickers Construction And Working Principles